Paper is to print, what canvas is to painting—you cannot have one without the other. As a designer, it is important to know that your choices around paper will impact the final output. The suitability of the stock when selecting paper for your print project includes a number of considerations. Let’s take a look:

Types of Paper

Paper, how it looks and feels, is going to have a big impact on the final printed result. And as such—should be an important design consideration early on in any project. Paper can be classified into six basic categories as follows:

Uncoated Papers:

These have a raw natural appearance and offer a range of textures, from toothy to very smooth. Uncoated papers tend to be more absorbent (refer to Dot Gain, page 81) which lend themselves to a softer image with warmer colours and a natural feel. Uncoated papers are more suitable for writing on.

Coated Papers:

These papers and boards have a fine clay coating added during manufacturing. This coating provides a smooth, high quality print surface resulting in brighter colours and sharper images. Coated papers come in varying degrees of sheen—from low to high: matt, satin, silk and gloss. Note that both Coated and Uncoated stocks are ‘commodity’ grades—meaning they are suitable for all budgets.

Creative Papers:

Premium stocks, offering unique and varying characteristics. Such as colours, textures (laid, hammer, vellum, felt, or linen surfaces), metallic finishes or frosting, special fibre content, improved brightness and whiteness, or combinations of these attributes. Many Creative Papers are premium ‘uncoated’ stocks—but some are completely different to standard paper. Creative Papers are great for getting more from paper in a creative way.

Synthetics:

Manufactured from non-wood-based materials—making these tear, moisture and often chemical resistant. Synthetics are perfect for projects subject to hard wear and tear (such as menus, labels and tags, point-of-sale material), or for projects destined for outdoor use (such as signage or field manuals).

Self Adhesives:

These ‘labels’ come in a huge range of facestock options (the sticker part) and adhesive strengths to suit different applications. Such as wine & beverage labels, frozen foods, agricultural products, etc.

Boards:

Heavier-weight cardboard stocks used predominantly for packaging, but in some instances can also be used for making folders or document covers. The Boards range includes options that are coated and uncoated, plus a number of special-use stocks.

Specifying Paper

Knowing that paper is a considered part of the overall design of a project— means choosing stock is really important. As the designer, you are entitled to nominate what stock your project is printed on. Here are some things to think about when looking at paper;

- The look & aesthetic of the stock

- The cost/budget

- The suitability of the stock

- The sustainability of the stock

When specifying paper, we recommend liaising with your BJ Ball / Ball & Doggett paper consultant and your printer.

Look & Aesthetic

The look of paper varies enormously. We’re not going to give advice on what looks good (we’ll leave that to you)—other than to say, when thinking about look & aesthetic, keep in mind that the whiteness, colour, texture and surface quality of the stock will likely affect the printed colour. Whiter stocks result in brighter colours. Off-white or coloured stocks will cast colours. Importantly, this may noticeably affect printed skin tones in photos.

To help you make choices in relation to stock, BJ Ball and Ball & Doggett provide a free sampling service available via our respective websites (your printer can also request samples from us on your behalf). Using this service—we will send you physical stock samples and/or mock-ups so you can sight your paper choice to ensure this matches what you are thinking. Make use of this service—it is free and available to you. Don’t forget you can call us to discuss your project—we know paper and can help guide you through the decision making process. Our contact details are on the back cover of this document.

Budget

When you are working on a print project—you will not know the cost of production until your printer supplies an estimate or quote for the job. However, can paper account for a considerable percentage of the total cost of a print project. Here are some things to keep in mind in relation to costs;

- Coated and Uncoated Papers: are generally more cost effective than stocks from the other categories

- Synthetics: are more expensive than wood-based papers, but may offer better value over the lifetime of the piece depending on the intended use

- Creative Papers: are (generally) more expensive than Coated and Uncoated Papers—however, we do try to stock a range of grades to fit your budget, so it pays to ask

- Weight and thickness matters: Going up or down a weight can make a noticeable difference to the overall print cost—as a suggestion, cost a project on two different weights to compare

- Cost your project ‘two or three ways’: It can often be a good idea to ask your printer to cost the project on two or three different stocks

- Form a close relationship with your printer as they can provide expert advice when considering different stock options

Suitability Of The Stock

We can split the suitability of the stock into four different areas;

- The suitability of the stock to the intended Print Process

- The suitability of the stock to any Specials or Embellishments

- The suitability of the stock to the intended purpose/use

- Special considerations (packaging & labelling projects only)

Suitability Of Stock To Print Process:

| Print Process: | Stock Suitability: |

| Offset Lithography (Sheet-Fed): |

|

| Offset Lithography (Web-Fed): |

|

| Flexography: |

|

| Rotogravure: |

|

| Laser-Printing: |

|

| Inkjet-Printing: | Subject to testing:

|

| Risography |

|

| Letterpress |

|

Note: Very thick Board weights (400um+), may require printing by a packaging specialist using a different process to those listed above.

Suitability Of The Stock To Specials Or Embellishments:

- Die-cutting: Most stock types can be die-cut—but this process suits thicker weights 150gsm, or heavier, as lighter stocks may tear during or after the cutting process

- Embossing & Foiling: Most stock types can be embossed or foiled (with the exception of some Synthetics). Best suited to weights 150gsm or heavier as thinner stocks may not be robust enough for the process. Foiling is best suited to stocks with smooth surfaces as opposed to textured

- Folding: Most stock types can be folded. Some thicker weights (300gsm+) should be scored and creased prior to folding to avoid cracking (refer to side story ‘Paper Grain’. Testing the foldability of a stock to a specific project is advised—talk to your printer

- Metallic Spot Inks (not metallic toners): Metallic Spot colour inks such as Pantone Golds or Silvers will print ‘truer’ and with more lustre on Coated Papers and Boards—as opposed to anything without a coating

- Spot UV: Spot UV can be applied to most stocks—but is best suited to coated stocks with a smooth surface as opposed to textured. Note, if using an uncoated stock, the first hit may absorb into the stock and so several hits may be required for the best effect

Suitability Of The Stock To The Intended Purpose/Use:

- Bulk: For projects that are a single sheet or only a few pages, using a bulkier stock (heavier weight) will help reduce the finished project flopping in the readers hands

- Constructability: The ability of stock to fold is a critical consideration in box packaging—see overpage

- Durability: Thin stocks will wear & tear much faster than thicker stocks, which may be an issue if a project is expected to be read repeatedly. This is where Synthetic grades come into play

- Mailing Costs: If a project is destined to be mailed or couriered out to a reader; the weight of the final printed piece can considerably affect the dispatch cost. Opting for a lighter stock weight may help in this area. Contact us to request a dummy mock-up—this will enable you to ascertain mailing costs

- Opacity: This is particularly important for any project that is double-sided or multi-paged; if the stock is too thin—show-through can occur where one side ghosts through to the reverse under normal lighting conditions. Weights of 120gsm+ will usually stop this occurring

- Project Lifespan: Some projects may need to last over a long period of time. In this situation, stock choice can have a dramatic affect on the way the project ages—choosing an archival or pH neutral stock can greatly improve the usable lifespan of a project (see side story).

Special Considerations For Board-Based Packaging

There are a number of different types of boards suitable for packaging projects— but it is important to understand that not all boards are suitable for all types of application. Here are some things to consider when thinking about packaging:

There are a number of different types of boards suitable for packaging projects— but it is important to understand that not all boards are suitable for all types of application. Here are some things to consider when thinking about packaging:

Box Packaging:

If your project is Box packaging—you should use a Folding Box Board (FBB) grade stock. FBBs are produced specifically for this purpose and will fold better than other stocks.

Food Contact:

Any board that comes in contact with food needs to be foodgrade certified (dry foods) so the stock does not leech and taint the food. This is a food safety regulation. Direct contact with fatty or fried food (such as chip or burger boxes) need to be food grade certified for fatty foods. This means the board is grease resistant, which ensures oil will not soak into the board, potentially causing the stock to fail—no one wants hot chips in their lap!

Moisture Resistant:

Board-based packaging that is exposed to moisture (chillers or freezers) need to be wet strength (for moisture) or freezer grade (for freezers) to ensure the integrity of the packaging—nobody wants to discover the cardboard six-pack isn’t up to the job when they lift their beers out of the fridge.

Product Protection:

When thinking about board-based packaging for retail products—this type of packaging needs to withstand the demands of shelf life (potentially a lot of handling) and protect the product inside. Stock weight may be a key consideration in relation to this.

Product Promotion:

Also on the subject of retail packaging; As marketers say—packaging is the silent salesperson. This means the stock needs to provide a high quality surface on which to print any graphics. This does not mean that you cannot use non-white or textured boards (like Kraft Board), but keep in mind the stock will affect the printed outcome.

Special Considerations For Labelling

When it comes to labels—there is a huge range of options in facestocks (the sticker part) and varying types and strengths of adhesive. The reason for so many variations is because not all labels are suitable for all uses. Here are some things to consider when thinking about self-adhesive stocks used for labelling:

- Adhesive strength is very important and is often determined by what the label is being stuck to—for example, labels applied to many types of plastic need an extra permanent adhesive or they will peel.

- In applications where the sticker is applied directly to food—the label needs to be food grade certified or the adhesive may leech into, and taint, the food (a food safety regulations issue).

- Labels applied to products that are exposed to moisture (such as stored in chillers) need to be wet strength or the sticker may peel or pull apart.

- Labels applied to products that are frozen, need to be freezer grade or the sticker may peel or pull apart

- Labels applied to curved shapes need to be conformable to wrap around the surface.

- Labels applied to products where durability or longevity is important—should ideally be made of a synthetic facestock—not paper. Synthetic stickers will significantly outlast paper-based products.

- Labels applied to products that are used outdoors need to be suitable for exposure to the elements. Outdoor Application labels have a synthetic facestock and strong water-proof adhesive to withstand tough environmental conditions.

- It may be an important consideration to know the ambient temperature within the environment in which the labels are being applied. Particularly if these are extremely hot or cold environments (such as commercial kitchens or packing plants for frozen products). The ambient temperature could potentially cause application issues with labels not suited to these conditions.

We recommend discussing your labelling project with your BJ Ball / Ball & Doggett representative and your printer. We also stress the importance of testing the product under actual application and end-use conditions prior to running the final project.

Special Stock Features

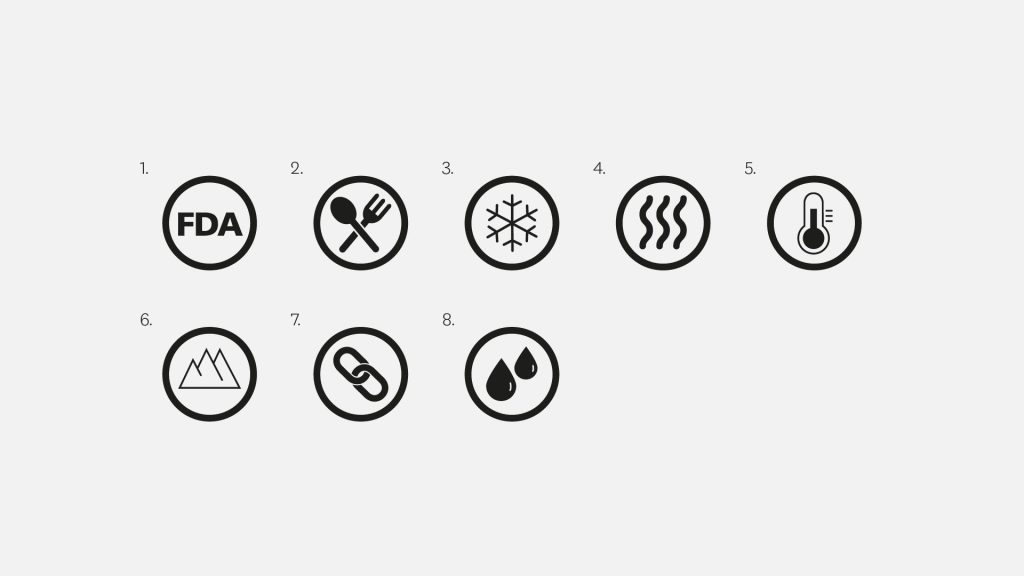

The above icons identify stocks within the BJ Ball / Ball & Doggett product ranges that provide specific product features related to the topics discussed on these pages:

The above icons identify stocks within the BJ Ball / Ball & Doggett product ranges that provide specific product features related to the topics discussed on these pages:

- FDA Approved: The US Food and Drug Administration (FDA) has approved this product as being safe for use with food products. However, as there are a number of variations of these certifications, it is important to contact BJ Ball / Ball & Doggett for clarification of compliance

- Food Safe: A product marked with this credential is suitable for use in food packaging, either direct or indirect. Please contact BJ Ball / Ball & Doggett for clarification on compliance

- Frozen Application: Products flagged with this icon can withstand temperatures as low as -5°C without compromising performance

- Heat Resistant: A product flagged with this icon can withstand end-use temperatures of up to +130°C without compromising performance

- Low Temperatures: A product flagged with this icon can tolerate low (chilled) temperatures without compromising performance

- Outdoor Application: A product flagged with this icon is resistant to environmental conditions and is suitable for outdoor use

- Tear Strength: A product flagged with this icon provides exceptionally high intrinsic strength. Ideal for uses where the printed piece may experience significant handling―such as packaging, restaurant menus, maps, manuals. Using a tear resistant stock can eliminate the need for lamination

- Wet Strength: A product flagged with this icon can be exposed to moisture without compromising performance

The Suitability of the Stock for Digital Print Processes

The above two icons identify stocks within the BJ Ball / Ball & Doggett product ranges which are pre-tested as suitable for use on specific forms of digital printing as follows:

The above two icons identify stocks within the BJ Ball / Ball & Doggett product ranges which are pre-tested as suitable for use on specific forms of digital printing as follows:

- Dry Toner Process: This credential represents that the product is suitable for use on digital laser print systems that are dry toner based (powder)

- HP Indigo: This credential represents that the product is suitable for use on HP Indigo digital laser print systems that are wet-toner based

These stocks can be ordered as digital papers supplied pre-cut to SRA3 (450mm x 320mm). As there is a significant variation between the many configurations of laser-printers; we recommend testing stocks through the specific system prior to running the final project.

Gsm vs Microns

Paper & boards can be measured in both weight or thickness—but these are not the same thing:

- Weight: is measured in Grams per Square Metre (GSM), worked out by taking one square metre sheet of stock and weighing it. Paper is more commonly specified using weight

- Thickness: is measured in Microns (µm)—short for Micrometre, which equals one-millionth of a metre! Boards are more commonly specified using thickness —particularly in the world of packaging. Thickness is more relevant in packaging for reasons of rigidity, foldability and strength

Note, two stocks can be of the same weight (gsm) but have different thickness (µm). This is due to several factors, the mix of fibres used to manufacture the paper (their length and density), and the way in which the paper has been made. For example, a coated grade is not as thick as an uncoated grade because the process of applying a coating flattens the fibres

Paper Grain

Paper is made primarily from wood pulp which is mulched and bonded together. This gives Paper a ‘grain’ of fibres which typically run parallel to each other. Papers can therefore be referred to as short or long grain defined as:

- Short Grain: The grain runs parallel to the short edge of the sheet.

- Long Grain: The grain runs parallel to the long edge of the sheet.

The reason that grain direction might be important is either to ensure the stock runs smoothly through printing machinery or for folding. For example, it is best practice to fold board stocks with the grain, as folding against the grain can result in cracking. Grain is also the reason why some stocks tear easier in one direction (with the grain). Particularly when producing box packaging—grain direction might determine the orientation of the sheet relative to the die-stamper; the preference is to have most folds going with the grain

Long-life Paper

The above two icons identify stocks within the BJ Ball / Ball & Doggett product ranges where extreme longevity is a requirement. For example: legal documents, use in libraries, museums, art galleries and other archives. These are:

The above two icons identify stocks within the BJ Ball / Ball & Doggett product ranges where extreme longevity is a requirement. For example: legal documents, use in libraries, museums, art galleries and other archives. These are:

- Archival 100 Years+: Archival stock will last a long time without significant degradation. Note however, this does not necessarily mean that printed colour will last (as this is also dependent on the colour-fastness of the ink used). Paper with this credential meets the ISO9706 standard for permanence

- pH Neutral: Stock with the pH neutral icon indicates that the paper has had, during the manufacturing process, the acid and alkaline levels balanced to a neutral state— giving it long life properties. This is particularly important where the stock is directly contacting other material —such as backing board or tissue to protect archives.

Recycled Paper

Paper is one of the most recycled products in the world— which is great news for the environment. Recycled paper makes the most of precious forest resources, reduces the pressure to harvest more trees and reduces landfill. The type of waste used to make recycled paper tends to originate from the following sources:

- Mill-broke waste: This specifically relates to trimmings, off-cuts and other scrap discarded during paper manufacturing

- Pre-consumer waste: Is waste from the printing process, commonly consisting of trimming off-cuts and run-up sheets. The printer recycles this material

- Post-consumer waste: Anything discarded after consumer use, such as cartons, magazines, newspapers (think of your recycling bins)

One of the challenges with making recycled paper using waste is that the fibre strength diminishes when the paper is turned back into pulp. For this reason, many recycled papers suitable for high-quality printing are made by adding virgin fibre into the mix. This ensures the paper is strong enough and provides a quality surface for printing. Paper can be re-pulped many times, until eventually the wood fibres break down to the point it is no longer usable. At this point, the waste goes to landfill where—because paper is made from wood (a natural material)—it biodegrades and breaks down.

Workflow for Specifying Paper:

- Start by thinking about the ‘look’ you are going for. Use the available tools—particularly our swatch books, and sampling service—to sight the stocks

- Make a short-list of preferred stocks

- The suitability of the stock is important. Discuss your stock choice with your BJ Ball / Ball & Doggett Paper Consultant and your printer

- Your printer can then quote your project. If you are working to a set budget, and the quote comes back outside this range—talk to your printer. You may find something as simple as dropping a weight grade may bring the project back within budget

- Lastly, don’t forget to get the client on-board!

An important aspect that is often overlooked is showing the paper choice/s to the client—remember it’s their money. A stock sample or a document mock-up is ideal for this purpose as the client can hold it, see it, feel it.